Innospection

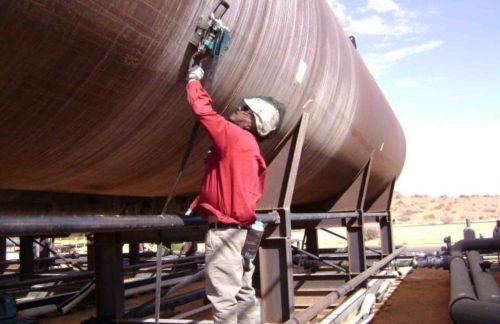

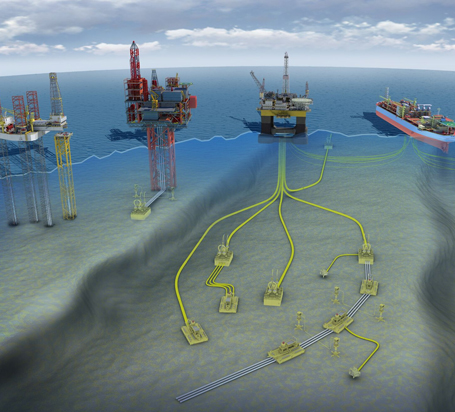

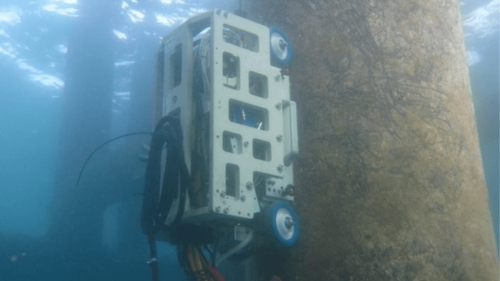

Innospection, now a division of Sonomatic Limited, is a provider of advanced inspection services for the integrity and lifetime assessment support of onshore and offshore topside, splash zone and subsea assets. We offer innovative and unique R&D solutions to solve standard and niche inspection challenges. In addition, the Group has sole ownership of an extensive portfolio of patents with respect to MEC™ (Magnetic Eddy Current Technology) tooling and its application method.