As large amount of the subsea pipelines are non-piggable and the internal inspection with the installation of subsea launcher and receiver involves huge costs, Innospection has developed an external inspection package able to access and scan the non-piggable subsea pipelines, subsea flowlines and manifold pipes.

Subsea Pipelines

Non-Piggable Subsea Pipeline Inspection

- High inspection speed with a typical coverage of 10m/min.

- Ability to inspect at various subsea depths.

- Ability to inspect through coating such as TSA.

- Ability to detect internal and external corrosion and defects including isolated pits of very small diameter and volume.

- High defect detection sensitivity in assets with OD from 6" to flat, wall thickness up to 25.4mm (1") - higher WT on request and coating thickness up to 15mm.

Concrete-Coated Subsea Pipeline Inspection

- Inspection system deployable by divers or ROV.

- Detection for each footprint area from 10-20% wall loss and defect size from OD 40-50mm

- High wall loss detection capability in assets with OD 12” to 20” and coating thickness up to 250mm

- In addition to subsea pipeline inspection, Innospection also offers condition assessment of subsea manifold pipes and Subsea corrosion mapping and geometry measurement of subsea structures which have been reused and repaired.

MEC™ Technique & Crawlers

MEC™ (Magnetic Eddy Current) is a dynamic electromagnetic technique that supports the Non-Intrusive Inspection (NII) strategy.

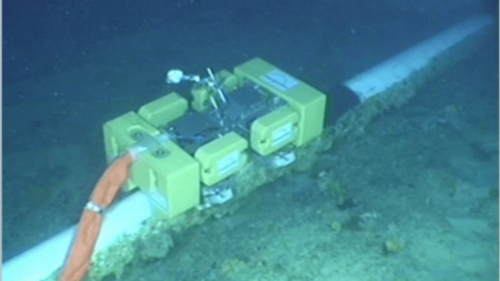

The fleet of sophisticated MEC™-Combi Pipecralwers are designed and built to support subsea integrity assurance as well as to target inspection, deployment and subsea accessibility challenges.

- Ability to inspect through higher wall and coating thickness.

- High sensitivity in detecting internal and external defects including small and shallow pitting defects (from Ø >3mm and 10% wall loss).

- Direct sizing of defects during scanning without the need for Ultrasonic verification with accuracy of +/- 10% for onsite reporting and +/- 5% for special offline analysis.

- Analysis of defect severity in terms of wall loss and volume.

- Separation of noise signals from defect signals.

- Enables fast scanning and C-scan mapping.

- Cleaning of the asset down to its bare metal to produce good quality data is not necessary which is a major advantage over Ultrasonic capabilities.

- Cost effective inspection solution.

- Deployable by divers or ROV from support vessels.

- Capable of self-crawling along the inspection surface to perform the scanning in axial and/or circumferential orientation.

- Ability to remain in stable contact with the inspection surface despite the turbulences and waves due to its integral buoyancy and magnetic system.

- Comprehensive inspection data within a single deployment through the incorporation of supporting inspection techniques: High resolution Ultrasonic mapping, Pulsed Eddy Current Testing (PECT), Laser triangulation system and Camera System.

PECT Technique & Scanners

The PECT inspection of subsea pipes with OD from 12” to 20” is currently performed with the diver deployed Subsea MDSA-1D-12-20 PECT Scanner for axial scanning or Subsea MDSA-2D-12-20 PECT Scanner for axial and circumferential scanning.

The PECT equipment consists of a ruggedised, splash water tight tablet computer connected to a data acquisition unit and subsea probe. A semi-automatic scanning ring has been developed to improve the inspection performance, particularly the timing and reproducibility.

The electric motor of the scanning ring enables the circumferential step movements to be fully and remotely controlled by the operator.

The signal data is transferred in real time via the umbilical to the inspection computer located on the installation or support vessel to provide instantaneous inspection results. The advanced reporting software utilises a combination of comprehensive C-Scan mapping, individual defect sizing analysis and matrix data to provide a reliable and extensive condition assessment.

- The latest generation PECT (Pulsed Eddy Current Testing) technique offers the following benefits:

- Enhanced wall loss detection capability.

- Ability to inspect through 250mm coating to detect corrosion and defects beneath.

- Highly repeatable results which makes it well suited for the wall thickness monitoring of coated assets.